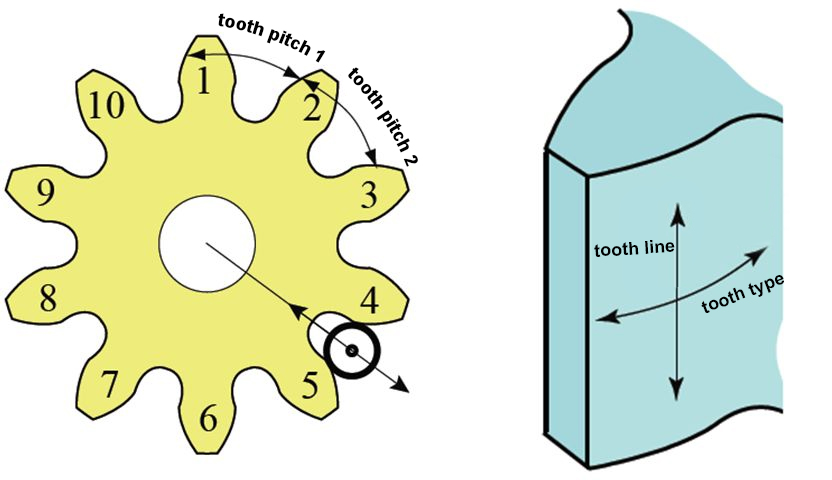

The accuracy of gears can be roughly divided into three categories:

a) Correctness of involute tooth profile – tooth profile accuracy

b) The correctness of the tooth line on the tooth surface – the tooth line accuracy

c) Correctness of tooth/gap position

• Tooth indexing accuracy—single pitch accuracy

• Pitch Correctness – Cumulative Pitch Accuracy

• Deviation of the radial position of the ball clamped between the two gears – radial runout accuracy

Scan the gear under test, and build the actual model of the gear under test through the scanned data; overlap the actual model of the gear under test with the standard 3D model; compare the selected sections of the overlapping models; judge whether the points on the actual model section are not Outside the tolerance zone selected on the actual model. The method makes the measurement data of the gears intuitive and easy to understand, and does not require too professional technical background; it can eliminate the need for professional gear measurement equipment and reduce the investment of professional instruments; the data information is comprehensive, and the data characteristics of the tooth surface can be fully controlled, and the The measured data can be directly read into the design or analysis software for use; high efficiency can be used for online measurement of mass-produced gear parts, making product quality easy to manage; it can be applied to the systematic management, tracking and complex data of gear products. Data analysis applications.