In recent years, silicone tubes have been widely used in modern industries, defense industries and daily necessities such as aviation, electronics, petroleum, chemical industry, machinery, electrical appliances, medical care, ovens, and food. Its basic purpose is the safe and efficient transfer of specific kinds of fluids, liquids or gases in a given physical, mechanical and chemical environment. Silicone tubing is more used in the transportation, automotive and shipbuilding industries, in the automotive industry. It is mainly a silicone tube used for water cooling and intercooling systems of automobile engines.

Although the silicone tube is an industrial silicone tube, the requirements for quality and performance are also very strict. The application of silicone tubes in the industry is also used in many important systems, and they play a very important role, so the product performance requirements for silicone tubes are also very strict.

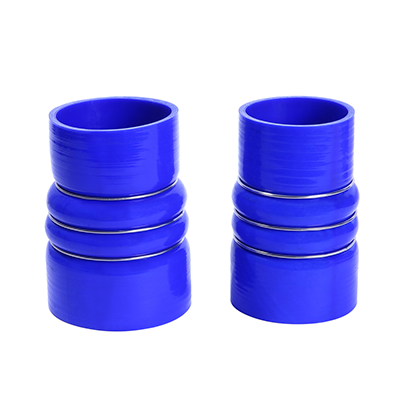

Silicone tube is a kind of connection needs that can meet the needs of some large equipment, as well as the needs of catheters. This silicone tube has high elasticity, high elasticity, compression resistance, and long-term use without deformation. At the same time, it can also play a flame retardant role. The silicone tube that is widely used now is made of imported silicone. All are non-toxic, odorless, environmentally friendly, and have the excellent characteristics of high transparency.

Compared with ordinary rubber tubes, silicone tubes have better heat resistance. They can be used in a high temperature environment below 150 degrees without any change in performance, and can still be used in a high temperature environment of 200 degrees Celsius. The effect of using 10,000 times has not changed any performance, so more and more applications are now using large-diameter silicone tubing to replace the original rubber tubing. This change has also increased production security several times. Large diameter silicone tubing has strict requirements.

Silicone tube has excellent electrical insulation properties, aging resistance, chemical stability, oxidation resistance, corrosion resistance, radiation resistance, physiological inertia, good air permeability, high and low temperature resistance, and can be used for a long time at -60℃~250℃. A variety of color options provide the advantage of better aesthetics and are widely loved by everyone. Contact us to order reliable and affordable silicone tubing.