Advantages:

• Compared with traditional ductile iron, ADI has higher strength, toughness and wear resistance.

• Compared with steel, it has better cost performance and lower density, which can reduce the weight of the structure.

Challenges:

• The production process is relatively complex, and the time control and temperature control of austenite step quenching need to be strictly managed.

• In some high temperature or special corrosive environments, the corrosion resistance of ADI may be insufficient and additional surface treatment is required.

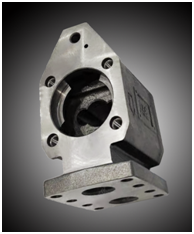

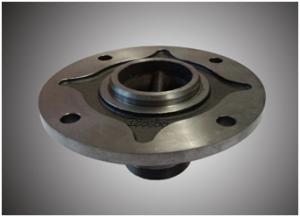

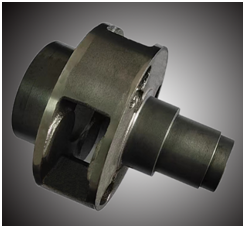

Hiwowsport ADI Products,Tensile strength ≥1400Mpa,Elongation>2%Good damping capacity, goodwear resistance, high bendingfatigue and contact fatiguestrength (equivalent to low.alloy steel), light weight (10%lighter than steel).To know more,please contact Maggie@hiwowsport.com