In order to let you quickly understand the sea flower hose, here are some key technical indicators:

1、Difference between elasticity of silicone rubber tube and latex tube

The hardness of the common silicone hose is mostly 70A-75A, which is the common hardness of many customers. However, Haihua can also be customized for special hardness requirements. The hardness of the latex hose is softer than that of the silicone hose, so its elasticity is better

2、working temperature

The temperature of the silicone tube is between – 60 ℃ and 200 ℃. If we are careful at ordinary times, we will also find that some parts on the air conditioner use silicone tubes. The silicone tube is working normally. Its normal working environment, from the lowest temperature to the highest temperature, makes the air conditioner play a role of fan heat and insulation. For example, the normal operating temperature of our silicone hose is – 60 ℃ to 200 ℃, because we know that many products will be sold everywhere. Some places are cold and some places are hot, so it has a certain range of application. Our product temperature label indicates that it can be used normally at this temperature. Once it exceeds the normal operating temperature, it may not guarantee its service life, It may not work normally. The normal temperature we are talking about here is that the silicone rubber tube can provide insulation protection. If the temperature exceeds this temperature, it may not work.

3、Application of silicone hose

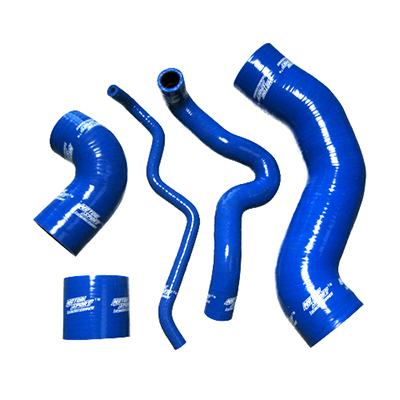

High-temperature resistant silicone hose produced by Haihua can be used in the fields of aerospace, instrumentation, railway transportation, electrical appliances, household appliances, modified cars, etc.

4、colour

The conventional color of the silicone tube produced by Haihua is black, and the conventional colors are red, yellow, blue and green. For some special colors required by customers, as long as the minimum order quantity is reached, we can also customize the production.

For more details about Haihua silicone hose, welcome to consult Haihua!